Who doesn't know them - the little sweets for between meals or as an evening snack? Sweets are available in almost any form, whether as sweet or salty fruit gums or as chocolate with cookies or fruit. They come in a wide variety of flavors and mixtures. However, to ensure that popular snacks and sweets are available in stores every time, appropriate primary packaging, ideally in the form of pouches, is necessary.

The primary packaging requirements are low packaging costs and high product protection. In the case of cookies, product breakage must be minimized during filling. On the other hand, soft products, such as fruit gums, must be prevented from sticking during dosing.

We aim to produce perfect pouches at the lowest unit costs and reliably over the entire service lifetime of the machine.

High flexibility

for a wide variety of products

We know confectionery and snacks in all imaginable shapes and varieties. It starts with sweet and salty to chocolaty and fruity. Primary packaging is essential to provide the best protection for these popular products and to increase shelf life. It protects the product from external influences and is a visible advertising space. Many different product variants and characteristics require a flexible and easy-to-operate packaging machine. Multi-head weighers are usually used to fill snacks and confectionery. They combine the target weight from several independent weighing cells and transfer it to the packaging machine with precise timing.

Gentle and smooth product filling

with individual versions of dosing systems

For smooth filling, it is important that soft products, such as fruit gums, do not stick to ensure a continuous product flow. In this case, we usually use smooth and slippery surfaces for parts that come into contact with the product. In the case of particularly brittle products, such as cookies or glazed confectionery, product breakage must be minimized. For this reason, we install gentle and soft flaps to reduce the drop height and soften the impact.

Product and pouch variants

thanks to many suitable pouch shapes and pouch sizes

Combined with our pouch packaging machines, single-serve units with small filling quantities, such as 100g, can be easily packed in flat or larger quantities, such as 1,000g, in stand-up pouches with zipper. For larger filling quantities, from around 500g, the filling can be distributed over two filling stations so that high cycle outputs can still be achieved.

You could produce consistently high speeds on our pouch packaging machines, even with high filling volumes. Single (simplex) to double (duplex) machines are generally used in the snacks and confectionery sector. Depending on the respective dosage, output rates from 70 to 120 pouches per minute are possible.

Quick and easy format changeovers significantly reduce the downtimes of our machines and ensure higher output and machine availability.

Packing and filling snacks and confectionery require different pouch formats and filling weights. In this case, the pouch packaging machine must be as flexible and convertible as possible. Many of our machines offer large format ranges so that most pouch formats can be produced on the same machine. Quick and easy changeover is a matter of course.

Low space requirement due to the rotary principle

We have always stood for horizontal rotary machines (HFFS). This machine principle requires little space in production, in particular, due to working with a rotary table. We can supply you with pouch packaging machines with integrated dosing systems from a footprint of 20 m².

The space advantages of our rotary machines become increasingly apparent, especially with multiple machines.

Furthermore, the control cabinet can also be integrated into certain machine models, which simplifies the handling and commissioning of the machine, saves space compared to an external control cabinet, and improves accessibility.

High-quality products deserve premium pouch quality

What matters when designing a pouch:

Stand-up bottom

An additional fold in the packaging material creates a pouch's stand-up base. This very stable base construction enables the pouch to stand independently on a flat surface. In addition to the primary function of being able to stand on its own, the stand-up bottom and the resulting bottom fold give the pouch a higher filling volume than a flat pouch. The bottom shape can usually be round, as in doypacks, or trapezoidal, as in deltapacks.

Zipper

A so-called zipper reclosure is often used to make the pouch reclosable. This zipper consists of two plastic lips that can be pressed together, pulled apart, and sealed into the top area of the pouch. This makes it possible to reclose the pouch after it has been opened for the first time and maintain the filling product's freshness to a certain extent.

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

Filling level

To minimize packaging material and costs, but also from a sustainability perspective, keeping the space between the product fill level and the top seam as small as possible is essential. Some technical processes, such as tightening before head sealing, require a certain amount of space in the headspace of the pouch. Headspace steaming, intended to counteract possible pouch inflation, also requires a certain amount of free space in the head area of the pouch. We are happy to help with the optimum design of the pouch dimensions depending on the intended filling quantity and filling level.

Overview of common pouch details

Details that really matter

-

Stand-up bottom

An additional fold in the packaging material creates a pouch's stand-up base. This very stable base construction enables the pouch to stand independently on a flat surface. In addition to the primary function of being able to stand on its own, the stand-up bottom and the resulting bottom fold give the pouch a higher filling volume than a flat pouch. The bottom shape can usually be round, as in doypacks, or trapezoidal, as in deltapacks.

-

Zipper

A so-called zipper reclosure is often used to make the pouch reclosable. This zipper consists of two plastic lips that can be pressed together, pulled apart, and sealed into the top area of the pouch. This makes it possible to reclose the pouch after it has been opened for the first time and maintain the filling product's freshness to a certain extent.

-

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

-

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

-

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

-

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

-

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

-

Filling level

To minimize packaging material and costs, but also from a sustainability perspective, keeping the space between the product fill level and the top seam as small as possible is essential. Some technical processes, such as tightening before head sealing, require a certain amount of space in the headspace of the pouch. Headspace steaming, intended to counteract possible pouch inflation, also requires a certain amount of free space in the head area of the pouch. We are happy to help with the optimum design of the pouch dimensions depending on the intended filling quantity and filling level.

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de

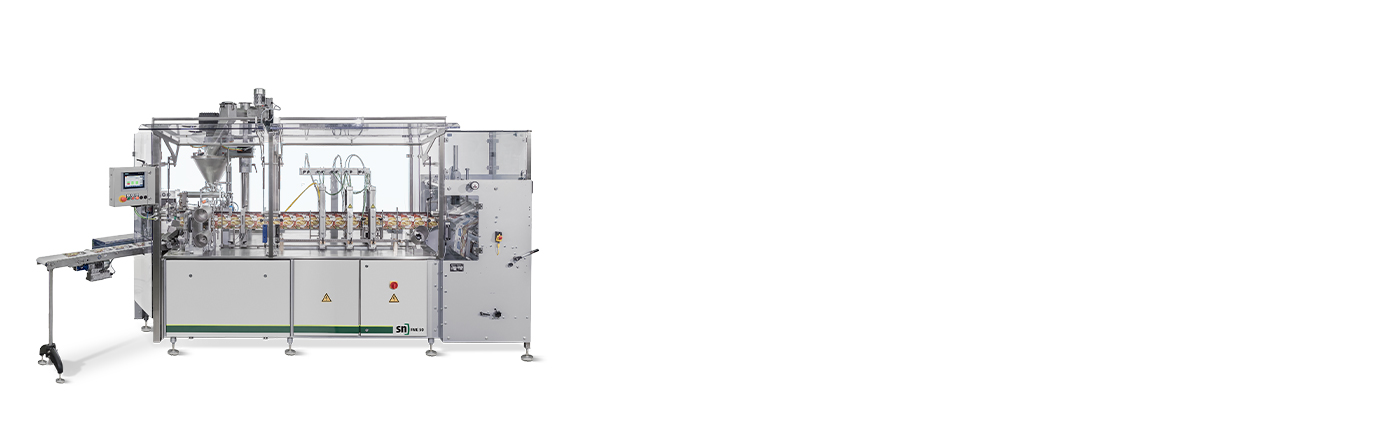

FME 50

Horizontal form, fill and seal machine (HFFS)

Format range pouch width

50 – 170 mm

Format range pouch height

70 – 210 mm

Realistic output rate

up to 70 pouches/min.

Exemplary yearly production output (single shift)

about 6 million pouches

(Data dependent on filling properties, pouch size, and production times)

FM 060

Horizontal form, fill and seal machine (HFFS) simplex

Format range pouch width

40 – 220 mm

Format range pouch height

50 – 250 mm

Realistic output rate

up to 70 pouches/min.

Exemplary yearly production output (single shift)

about 7.5 million pouches

(Data dependent on filling properties, pouch size, and production times)

FBM 22

Horizontal form, fill and seal machine (HFFS) duplex

Format range pouch width

120 – 190 mm

Format range pouch height

100 – 450 mm

Realistic output rate

up to 140 pouches/min.

Exemplary yearly production output (single shift)

about 45 million pouches

(Data dependent on filling properties, pouch size, and production times)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de