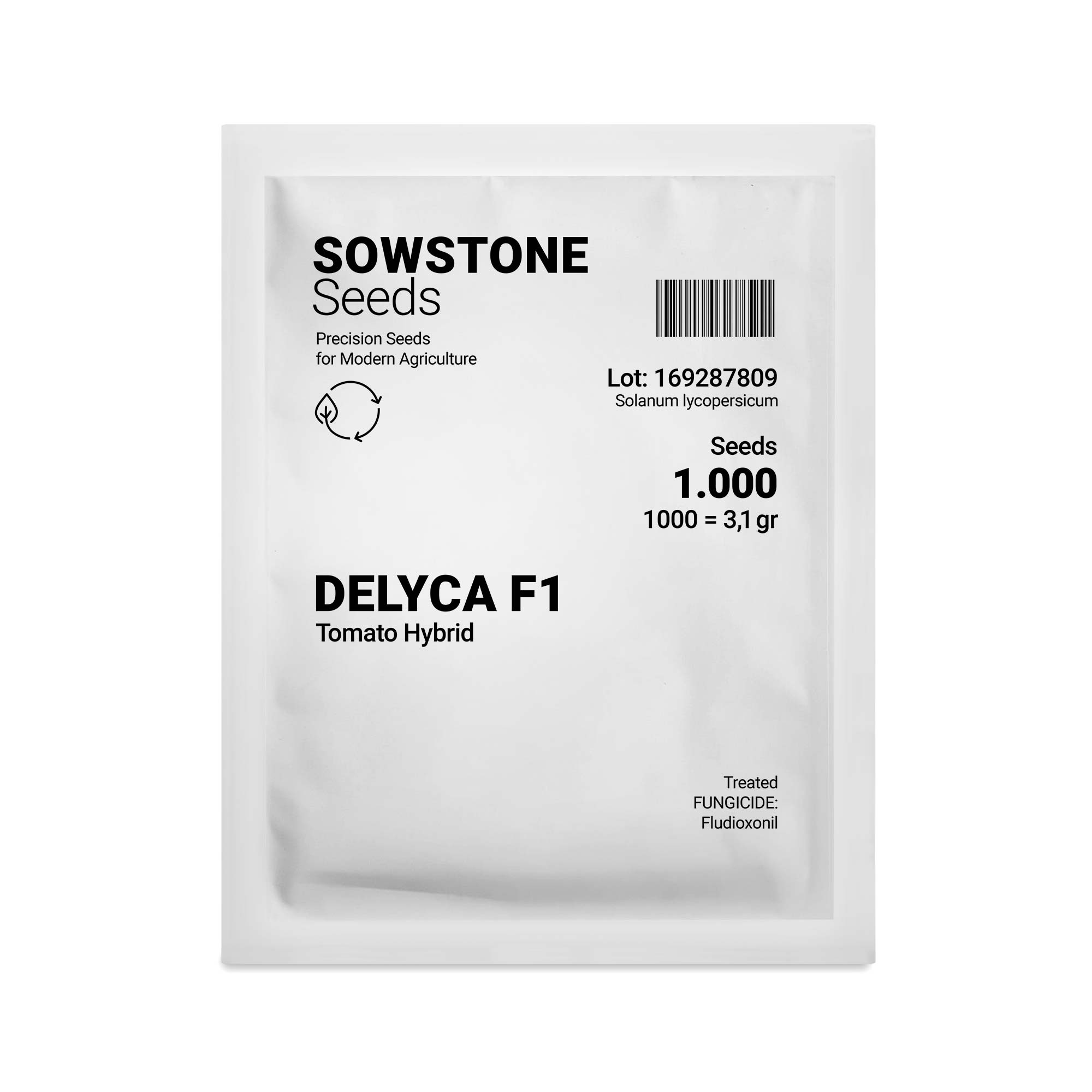

The growing conditions for vegetables, fruit, flowers, and plants vary significantly worldwide. Highly developed seeds can defy many adversities and grow even under challenging conditions. In this way, advanced seeds ensure consistently high yields in agricultural fields and plantations and ultimately contribute to feeding the world's population. High-performance primary packaging is essential to ensure the seeds are ready for dispatch and protected after development and refinement. Combining high-barrier films and high-performance packaging technology ensures that high-quality seeds are optimally protected for storage and worldwide transportation.

We offer flexible and reliable machine technology for the different requirements of seed packaging. The pouches can be produced cost-effectively directly from the roll or pre-filled and sealed as a flexible variant. Thanks to the integration of various printing and labeling devices, extensive coding and labeling of important seed information is no problem. Synchronization and integration with various dosing, weighing, and counting devices also matter to us.

Gentle and precise dosing

via in-house seed dosing systems

Multi-head weighers or high-performance counting devices are often used for filling and packaging large quantities of seeds. Integration and synchronization are possible without any problems. Our in-house seed dosing systems, such as volumetric or vibratory dosing systems, can also be flexibly combined with other dosing systems. A central dust extraction system effectively extracts dust. Gentle filling ensures that the seed's germination capacity and possible coating are always maintained.

Maximum product protection

through gentle filling

The development and refinement of the highest-quality seeds require a high level of expertise and process steps to ensure that they grow under the most challenging conditions and produce the highest possible yield. We are aware of this. We always focus on the gentlest possible filling process and maximum product protection.

High flexibility

thanks to the integration of various coding and labeling systems

Seed packaging usually requires a high level of additional information, which must be printed, lasered, or affixed to the pouch by label or booklet shortly before filling. For this purpose, we adapt our pouch packaging machines individually to the requirements. For example, several printers and labelers can be integrated directly into the machine on request. Cameras, scanners, and sensors can also be integrated to control print and content. Hand scanners can also be used, for example, to load production recipes into the machine automatically.

Decades of experience paired with the latest technology

Seed packaging has been a central part of our company's history for decades. We have seed packaging machines specially developed for this sector, which combine an optimum mix of proven and state-of-the-art machine technology. They are particularly robust and designed for long-lasting production runs.

High flexibility

Frequent product and format changes require a high degree of flexibility from the packaging machine. Our seed series machines can be changed over quickly, easily, and sometimes without tools. The integration of different dosing systems into the machine enables fast product changes. Of course, we also provide the necessary product marking technology, for example, by printing and, if required, labeling.

Reliable partner

As the world's leading manufacturer of pouch packaging machines for seeds, we are a reliable partner. Adding to the production of new machines, we have supplied service, maintenance, and spare parts for existing machines worldwide for decades. We can also carry out a general overhaul of existing systems so that production can continue successfully for many years.

High-quality products deserve premium pouch quality

The essence of designing a pouch

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

Sealing seam quality

Sealing seam quality is one of a pouch`s core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

Overview of common pouch details

Details that really matter

-

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

-

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

-

Sealing seam quality

Sealing seam quality is one of a pouch`s core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de

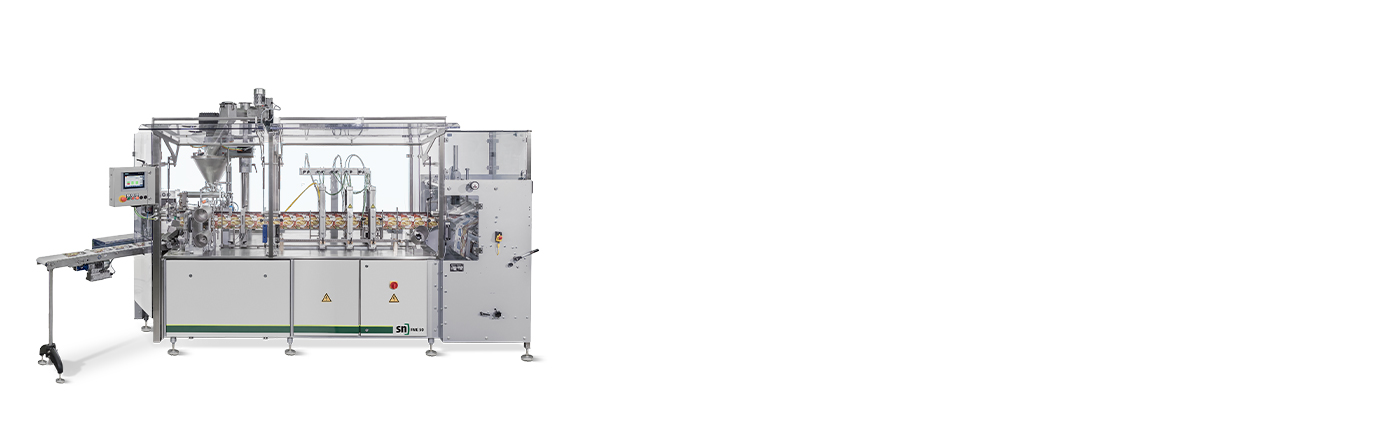

FME 50

Horizontal form, fill, and seal machine (HFFS)

Format range pouch width

50 – 170 mm

Format range pouch height

70 – 210 mm

Realistic output rate

up to 80 pouches/min.

Exemplary yearly production output (single shift)

about 6 million pouches

(Data dependent on filling properties, pouch size, material, and production times)

FM 060

Horizontal form, fill, and seal machine (HFFS) simplex

Format range pouch width

40 – 100 mm

Format range pouch height

50 – 250 mm

Realistic output rate

up to 160 pouches/min.

Exemplary yearly production output (single shift)

about 17 million pouches

(Data dependent on filling properties, pouch size, material, and production times)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de