Spices, herbs, and spice mixtures are an integral part of our daily diet. High-quality primary packaging ensures that consumers always receive freshly flavored spices, herbs, and seasoning mixes.

With decades of experience because of over a thousand machines on the market, we supply the perfect packaging technology.

High dosing accuracy

due to a minimal weight deviation of <1%

Powders and grounded spices must be dosed differently compared to whole grains or spice pieces. Dosing combinations are essential for multi-component or spice blends anyway. Here, we rely on decades of experience from over a thousand projects in the spice sector.

With our in-house dosing systems, we could continuously achieve the highest dosing accuracy of less than 1% weight deviation, resulting in minimal product loss.

Highest flexibility

through in-house dosing systems

With our in-house dosing systems, all conventional shapes and types of spices and herbs can be easily packed in single-serve units with small filling quantities of a few grams in flat pouches or an amount of several hundred grams in stand-up pouches with zippers. We offer different dosing systems for spices and herbs and can also combine different systems on one machine.

Up to 32,500 pouches per hour

With our pouch packaging machines, you can achieve maximum cycle outputs of up to 100 cycles per minute. In the simplex range (1 pouch per cycle), up to 6,000 pouches per hour are possible. In the top segment of 6-pouch machines (6 pouches per cycle), around 32,500 pouches per hour can be produced at a maximum of 90 cycles.

Coupled with minimal downtimes for format and product changeovers, we achieve machine efficiencies from up to 99%.

Quick and easy format changes in < 15 min.

Depending on the format and machine type, formats can be changed in a few minutes and almost without tools. Production and machine parameters for individual products and formats can easily be load in the operating panel (HMI) via integrated recipe management. Short format and product changeover times significantly reduce the machine's non-production time (downtime) and ultimately ensure higher machine utilization and greater productivity. With frequent product changes, as is usual with spices and herbs, short and easy set-up times are crucial.

Our dosing systems can be cleaned and set up quickly and easily, especially with frequent product and format changes. They can be archived directly in the machine (in place) or outside the machine. We also offer our dosing systems mobile for this purpose. For minimum downtime, double dosing systems or a second mobile dosing system are also available, which can be docked onto the machine and is immediately ready to use.

Low space requirement due to the rotary principle

We have always stood for horizontal rotary machines (HFFS). This machine principle requires a tiny space in production due to working with a rotary table. We can supply you with pouch packaging machines and integrated dosing systems from a footprint of 20 m².

The space advantages of our rotary machines are increasingly apparent, especially with multiple machines.

Furthermore, the control cabinet can also be integrated into certain machine models, simplifying handling and commissioning from the machine, saving space compared to an external control cabinet, and improving accessibility.

High-quality products deserve premium pouch quality

The essence of designing a pouch

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

Filling level

To minimize packaging material and costs, but also from a sustainability perspective, keeping the space between the product fill level and the top seam as small as possible is essential. Some technical processes, such as tightening before head sealing, require a certain amount of space in the headspace of the pouch. Headspace steaming, intended to counteract possible pouch inflation, also requires a certain amount of free space in the head area of the pouch. We are happy to help with the optimum design of the pouch dimensions depending on the intended filling quantity and filling level.

Overview of common pouch details

Details that really matter

-

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

-

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

-

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

-

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

-

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

-

Filling level

To minimize packaging material and costs, but also from a sustainability perspective, keeping the space between the product fill level and the top seam as small as possible is essential. Some technical processes, such as tightening before head sealing, require a certain amount of space in the headspace of the pouch. Headspace steaming, intended to counteract possible pouch inflation, also requires a certain amount of free space in the head area of the pouch. We are happy to help with the optimum design of the pouch dimensions depending on the intended filling quantity and filling level.

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de

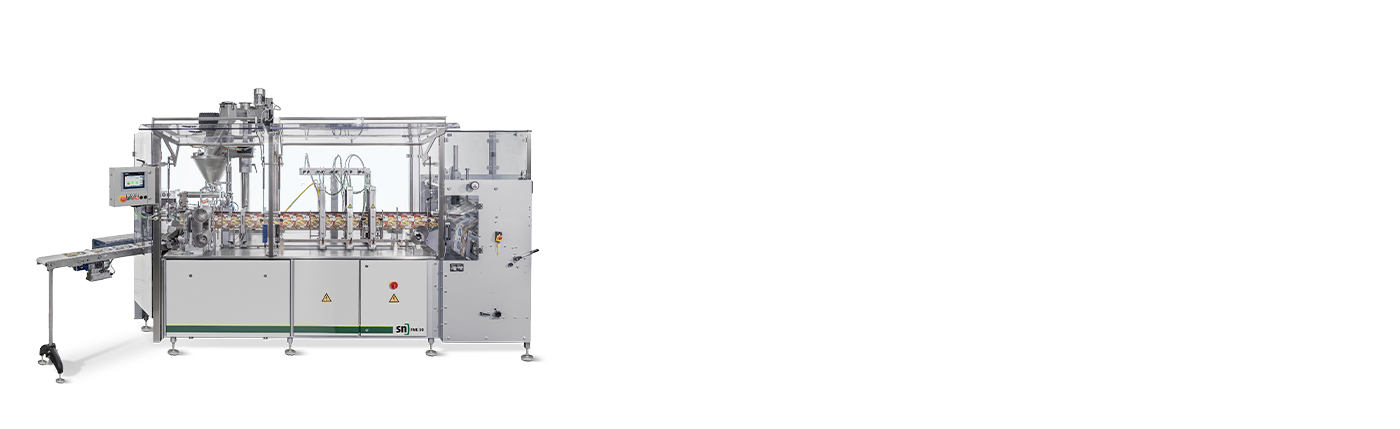

FME 50

Horizontal form, fill and seal machine (HFFS)

Format range pouch width

50 – 170 mm

Format range pouch height

70 – 210 mm

Realistic output rate

up to 100 pouches/min.

Exemplary yearly production (single-shift)

about 6 million pouches

(Data dependent on filling properties, pouch size, and production times)

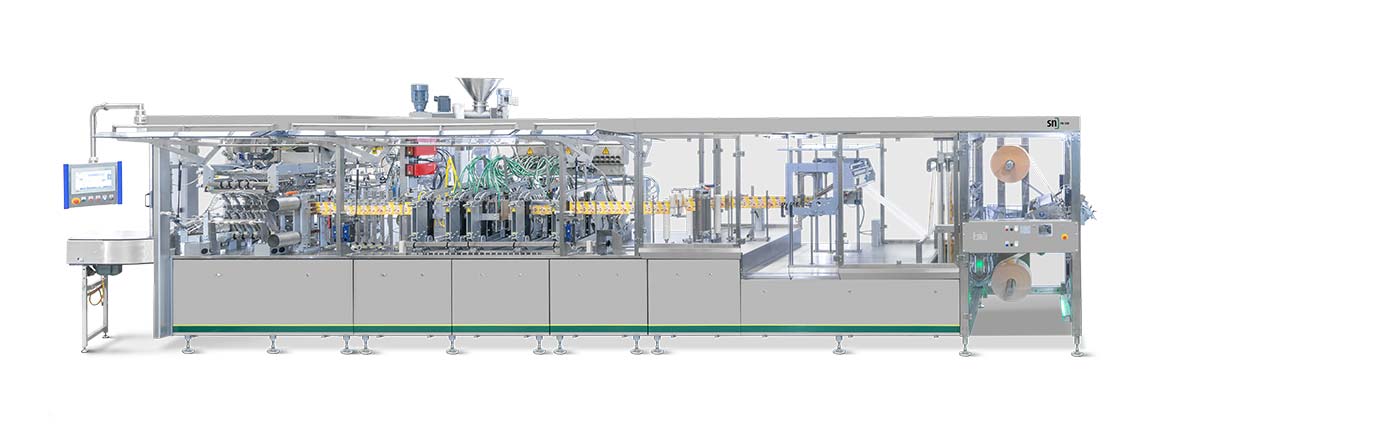

FBM 33

Horizontal form, fill, and seal machine (HFFS)

Format range pouch width

80 – 115 mm

Format range pouch height

120 – 250 mm

Realistic output rate

up to 270 pouches/min.

Exemplary yearly production (three shifts)

about 85 million pouches

(Data dependent on filling properties, pouch size, and production times)

FM 600

Horizontal form, fill, and seal machine (HFFS)

Format range pouch width

70 – 88 mm

Format range pouch height

100 – 210 mm

Realistic output rate

up to 540 pouches/min.

Exemplary yearly production (three shifts)

about 170 million pouches

(Data dependent on filling properties, pouch size, and production times)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de