As versatile as nuts and nut mixes are in terms of type, variety, and combinations, their pouch packaging is also versatile. To pack high-quality nuts and nut mixes economically and safely, high-quality primary packaging, for example, in the form of pouches, is essential. With decades of experience in packaging nuts, we build sophisticated and reliable pouch packaging machines made in Germany.

High output for every fill weight

via smart discharge management of the multi head weigher

Combined with multi-head weighers, our machines achieve maximum cycle outputs with high filling quantities. With the help of smart discharge management, our machine waits for small delays in the multi-head weigher and thus ensures more filled and sealable pouches. For larger product quantities, such as 500 grams, 750 grams, or 1,000 grams, filling can be divided between two stations. This means short filling times per station can be maintained and high speeds achieved.

Product protection

by minimizing breakage

Nuts such as almonds, macadamias, walnuts, and Brazil nuts differ greatly from one another, for example, in type, shape, and filling properties. However, nuts have one thing in common. They are all high-quality and valuable foods. Sensitive filling is required to ensure that the valuable nuts and nut mixtures reach the consumer as undamaged as possible. For example, short drop distances reduce product breakage to a minimum.

High speeds and output

Our pouch packaging machines produce at consistently high speeds, even with high filling volumes. Depending on the dosage, output rates from 60 to 210 pouches per minute are possible. For the nut sector, we recommend the production of single (simplex) to triple (triplex) machines.

Quick and easy format changeovers significantly reduce the downtimes of our machines and ensure higher output and machine availability.

Great flexibility for your pouch packaging

Everything is possible with SN Maschinenbau, from flat pouches to stand-up pouches with zipper reclosure. We also offer a wide selection of pouch dimensions and filling volumes. With different format ranges, we also have exactly the right machine for your product portfolio. Convertible machines allow you to change the machine modes very easily, for example, from simplex to duplex or duplex to triplex. That will further increase your flexibility.

Unique pouch quality, for which our machines have stood for years.

We adapt the pouch packaging machine individually to your pouch.

Stand-up bottom

An additional fold in the packaging material creates a pouch's stand-up base. This very stable base construction enables the pouch to stand independently on a flat surface. In addition to the primary function of being able to stand on its own, the stand-up bottom and the resulting bottom fold give the pouch a higher filling volume than a flat pouch. The bottom shape can usually be round, as in doypacks, or trapezoidal, as in deltapacks.

Zipper

A so-called zipper reclosure is often used to make the pouch reclosable. This zipper consists of two plastic lips that can be pressed together, pulled apart, and sealed into the top area of the pouch. This makes it possible to reclose the pouch after it has been opened for the first time and maintain the filling product's freshness to a certain extent.

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

Filling level

To minimize packaging material and costs, but also from a sustainability perspective, keeping the space between the product fill level and the top seam as small as possible is essential. Some technical processes, such as tightening before head sealing, require a certain amount of space in the headspace of the pouch. Headspace steaming, intended to counteract possible pouch inflation, also requires a certain amount of free space in the head area of the pouch. We are happy to help with the optimum design of the pouch dimensions depending on the intended filling quantity and filling level.

Hanger hole

The hanger hole is primarily used for easy placement on the shelf at the point of sale. The pouches with a (Euro) hole are pushed onto the shelf bars. The choice of hanger hole is up to you and is realized via a separate punch in the pouch packaging machine.

Overview of common pouch details

Details that really matter

-

Stand-up bottom

An additional fold in the packaging material creates a pouch's stand-up base. This very stable base construction enables the pouch to stand independently on a flat surface. In addition to the primary function of being able to stand on its own, the stand-up bottom and the resulting bottom fold give the pouch a higher filling volume than a flat pouch. The bottom shape can usually be round, as in doypacks, or trapezoidal, as in deltapacks.

-

Zipper

A so-called zipper reclosure is often used to make the pouch reclosable. This zipper consists of two plastic lips that can be pressed together, pulled apart, and sealed into the top area of the pouch. This makes it possible to reclose the pouch after it has been opened for the first time and maintain the filling product's freshness to a certain extent.

-

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

-

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

-

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

-

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

-

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

-

Filling level

To minimize packaging material and costs, but also from a sustainability perspective, keeping the space between the product fill level and the top seam as small as possible is essential. Some technical processes, such as tightening before head sealing, require a certain amount of space in the headspace of the pouch. Headspace steaming, intended to counteract possible pouch inflation, also requires a certain amount of free space in the head area of the pouch. We are happy to help with the optimum design of the pouch dimensions depending on the intended filling quantity and filling level.

-

Hanger hole

The hanger hole is primarily used for easy placement on the shelf at the point of sale. The pouches with a (Euro) hole are pushed onto the shelf bars. The choice of hanger hole is up to you and is realized via a separate punch in the pouch packaging machine.

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de

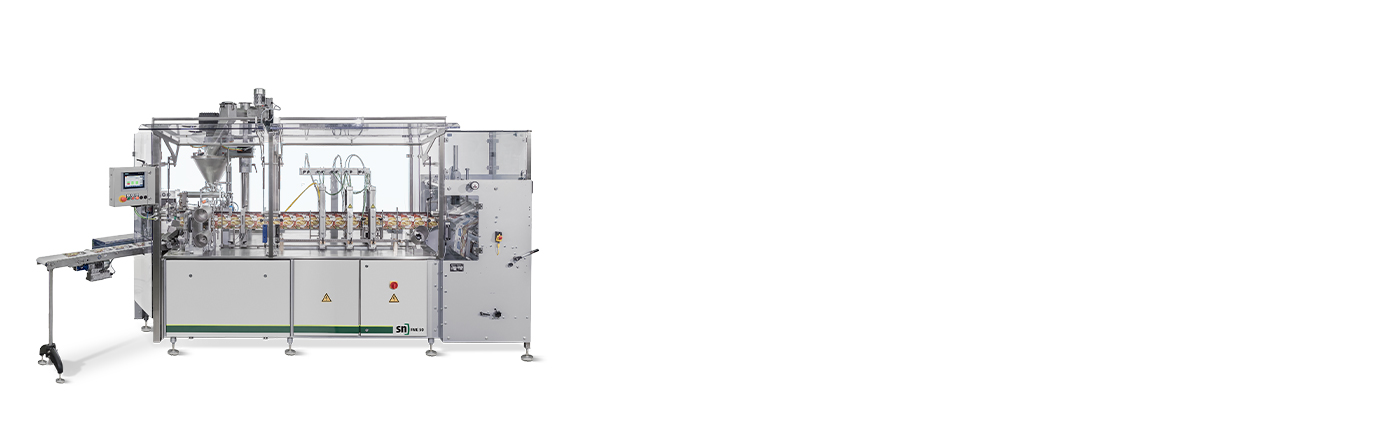

FME 50

Horizontal form, fill and seal machine (HFFS)

Format range pouch width

50 – 170 mm

Format range pouch height

70 – 210 mm

Realistic output rate

up to 60 pouches/min

Exemplary yearly production output (single shift)

about 6 million pouches

(Data dependent on filling properties, pouch size, and production times)

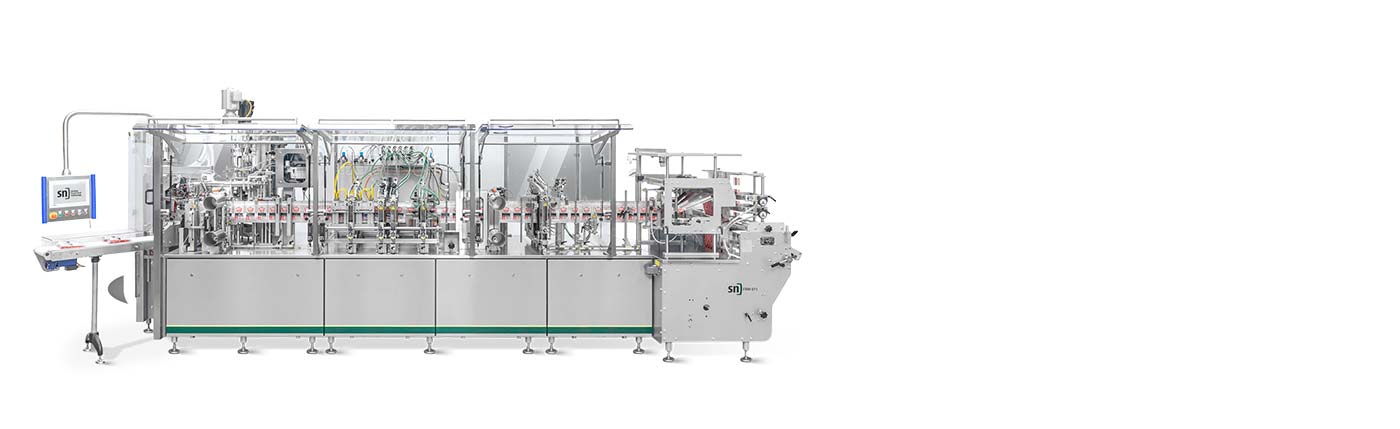

FBM 071

Horizontal form, fill and seal machine (HFFS) simplex

Format range pouch width

50 – 254 mm

Format range pouch height

80 – 350 mm

Realistic output rate

up to 60 pouches/min.

Exemplary yearly production output (single shift)

about 13 million pouches

(Data dependent on filling properties, pouch size, and production times)

FM 300

Horizontal form, fill and seal machine (HFFS)

Format range pouch width

100 – 191 mm

Format range pouch height

120 – 350 mm

Realistic output rate

up to 180 pouches/min.

Exemplary yearly production output (three shifts)

about 50 million pouches

(Data dependent on filling properties, pouch size, and production times)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de