Dry dog food comes in many different shapes and sizes. From complete food in small to large pieces to treats, snacks, and chew sticks. However, the packaging sizes for dry pet food also vary greatly. They range from packs of a few hundred grams to large pouches weighing several kilograms. With frequent format and product changes, quick and easy changeover from the machine is extremely important.

Whether produced from the roll (FFS) or as a pre-made pouch (FS), with decades of experience and many machines on the market, we supply the perfect pouch packaging technology for dry animal feed. Our machines combine the highest quality standards with precise dosing technology and maximum speed. We aim to produce perfect pouches at the lowest unit costs, reliably over the entire service lifetime of the machine.

Flexibility

in all performance ranges and filling quantities

We have the right machines for all capacity classes. From small quantities of complete feed with a filling weight of a few hundred grams to treats or chew sticks to large volumes of several kilograms in side-fold pouches. Depending on the pouch size, simplex, duplex, or even triplex machines are attractive to achieve the appropriate output. We rely on continuous filling and sealing for large filling volumes of several kilograms.

High performance for every fill weight

via smart discharge management of the multi-head weigher

Together with multi-head weighers, our machines achieve maximum cycle outputs with high filling quantities. With the help of smart discharge management, our machine waits for small delays in the multi-head weigher for more filled and sealable pouches. For larger product quantities, such as 500 g, 750 g, or 1,000 g, filling can be divided between two stations to maintain short filling times per station and achieve high speeds. High output rates can be achieved through continuous pouch filling and sealing when filling quantities of several kilograms.

Quick and easy format changes

Depending on the format and machine type, format changes are possible in just a few minutes and, in some cases, even without tools. Production and machine parameters for individual products and formats can easily be load in the operating panel (HMI) via integrated recipe management. Short format- and product changeover times significantly reduce the non-productive time (downtime) from the machine and ultimately ensure higher machine utilization and higher productivity.

Low space requirement due to the rotary principle

We have always stood for horizontal rotary machines (HFFS/HFS). This machine principle requires little space in production, due to working with a rotary table. We can supply you with pouch packaging machines with integrated dosing systems from a footprint of 20 m².

The space advantages of our rotary machines are becoming increasingly apparent, especially with multiple machines.

High-quality products deserve premium pouch quality

The essence of designing a pouch

Stand-up bottom

An additional fold in the packaging material creates a pouch's stand-up base. This very stable base construction enables the pouch to stand independently on a flat surface. In addition to the primary function of being able to stand on its own, the stand-up bottom and the resulting bottom fold give the pouch a higher filling volume than a flat pouch. The bottom shape can usually be round, as in doypacks, or trapezoidal, as in deltapacks.

Zipper

A so-called zipper reclosure is often used to make the pouch reclosable. This zipper consists of two plastic lips that can be pressed together, pulled apart, and sealed into the top area of the pouch. This makes it possible to reclose the pouch after it has been opened for the first time and maintain the filling product's freshness to a certain extent.

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

Overview of common pouch details

Details that really matter

-

Stand-up bottom

An additional fold in the packaging material creates a pouch's stand-up base. This very stable base construction enables the pouch to stand independently on a flat surface. In addition to the primary function of being able to stand on its own, the stand-up bottom and the resulting bottom fold give the pouch a higher filling volume than a flat pouch. The bottom shape can usually be round, as in doypacks, or trapezoidal, as in deltapacks.

-

Zipper

A so-called zipper reclosure is often used to make the pouch reclosable. This zipper consists of two plastic lips that can be pressed together, pulled apart, and sealed into the top area of the pouch. This makes it possible to reclose the pouch after it has been opened for the first time and maintain the filling product's freshness to a certain extent.

-

Tear opening notch

The tear-opening notch is a punched hole in the upper side seal seam of the pouch. This punching makes it easier for the consumer to tear open the pouch without tools and consume the contents. The tear-opening notch is usually designed as an incision or punched-out arrowhead.

-

Side sealing seam

The side sealing seam is the two sealed pouch edges and closes it in this area. The side sealing seam requires exceptional quality and strength. Its width can be freely selected according to the length of the pouch. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and sealing requirements. Optical and functional sealing patterns, such as cross and ripple patterns, can also be created in the sealing seam.

-

Top sealing seam

A top sealing seam permanently closes the pouch after filling. The side sealing seam requires exceptional quality and strength. Depending on the contents, filling quantity, and size, the pouch must be able to withstand various pressures and tightness requirements. In addition to the technical requirements, wider top sealing seams are often produced to give the pouch a corresponding appearance. Additional functions like hanging devices (euro hole or round hole) are integrated into the top seam.

-

Sealing seam quality

Sealing seam quality is one of a pouch core criteria. It must meet a wide range of quality and functional criteria. Thanks to our innovative and high-quality sealing technology, our machines can guarantee consistently high sealing seam strength over the long term. This also applies to different packaging materials and mono-materials.

-

Processability of mono-materials

All of our new machines can process recyclable mono-materials as standard. Thanks to innovative unwinding and sealing technology, new and thinner films and papers can be processed at the same quality and speed.

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de

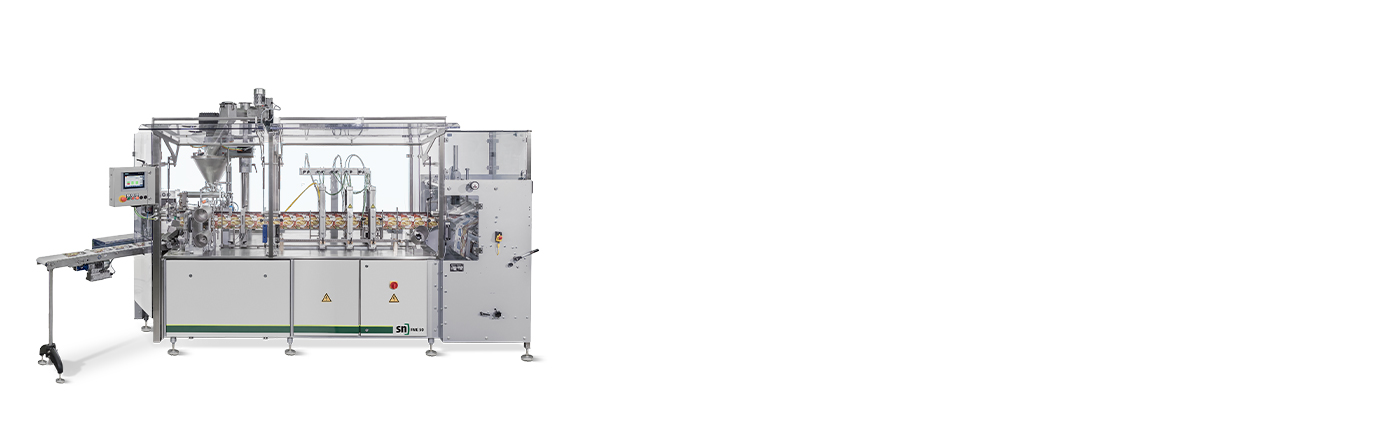

FME 50

Horizontal form, fill and seal machine (HFFS)

Format range pouch width

50 – 170 mm

Format range pouch height

70 – 210 mm

Realistic output rate

up to70 pouches/min.

Exemplary yearly production output (single shift)

about 6 million pouches/300 tons

(Data dependent on fillinf properties, pouch size, and production times)

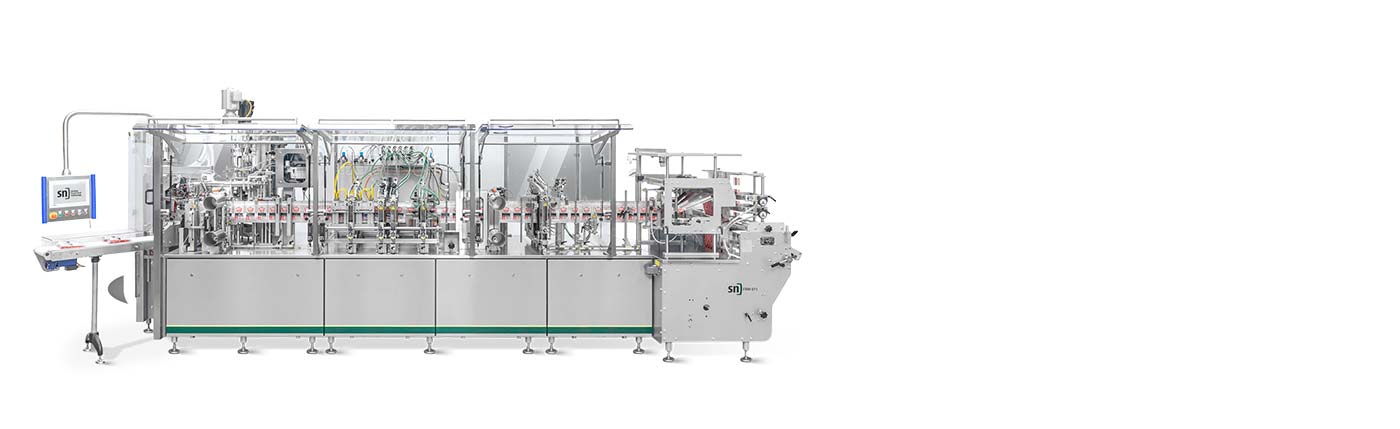

FBM 071

Horizontal form, fill and seal machine (HFFS) simplex

Format range pouch width

50 – 254 mm

Format range pouch height

80 – 350 mm

Realistic output rate

up to 70 pouches/min.

Exemplary yearly production output (single shift)

about 7.5 million pouches/5,500 tons

(Data dependent on filling properties, pouch size, and production times)

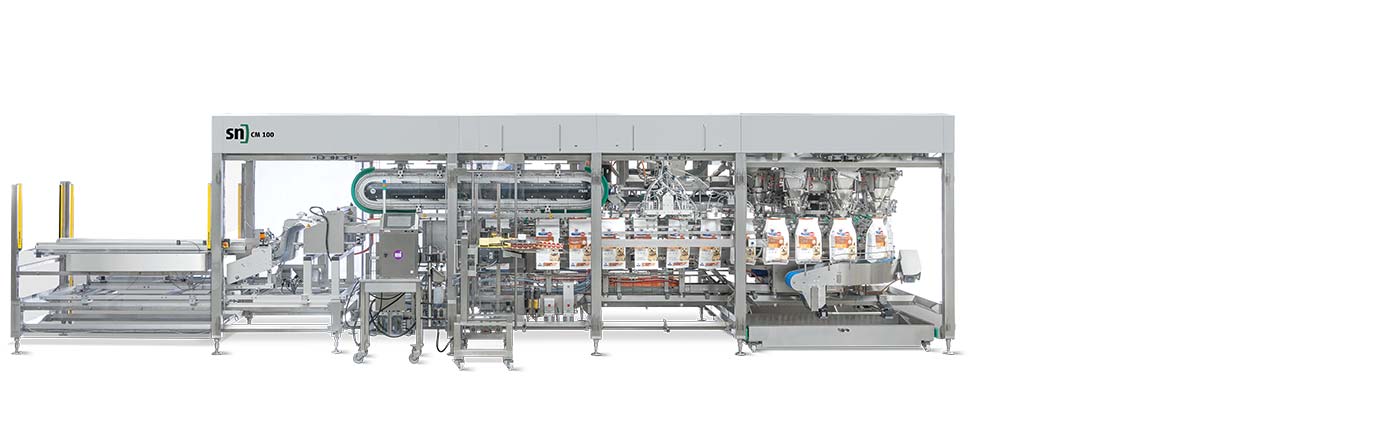

CM 100

Horizontal fill and seal machine (HFS)

for pre-made pouches

Format range pouch width

180 – 300 mm

Format range pouch height

270 – 640 mm

Realistic output rate

up to 50 pouches/min.

Exemplary yearly production output (three shifts)

ca. 16 Mio. Beutel / 75.000 Tonnen about 16 million pouches/75,000 tons

(Data dependent on filling properties, pouch size, and production times)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de