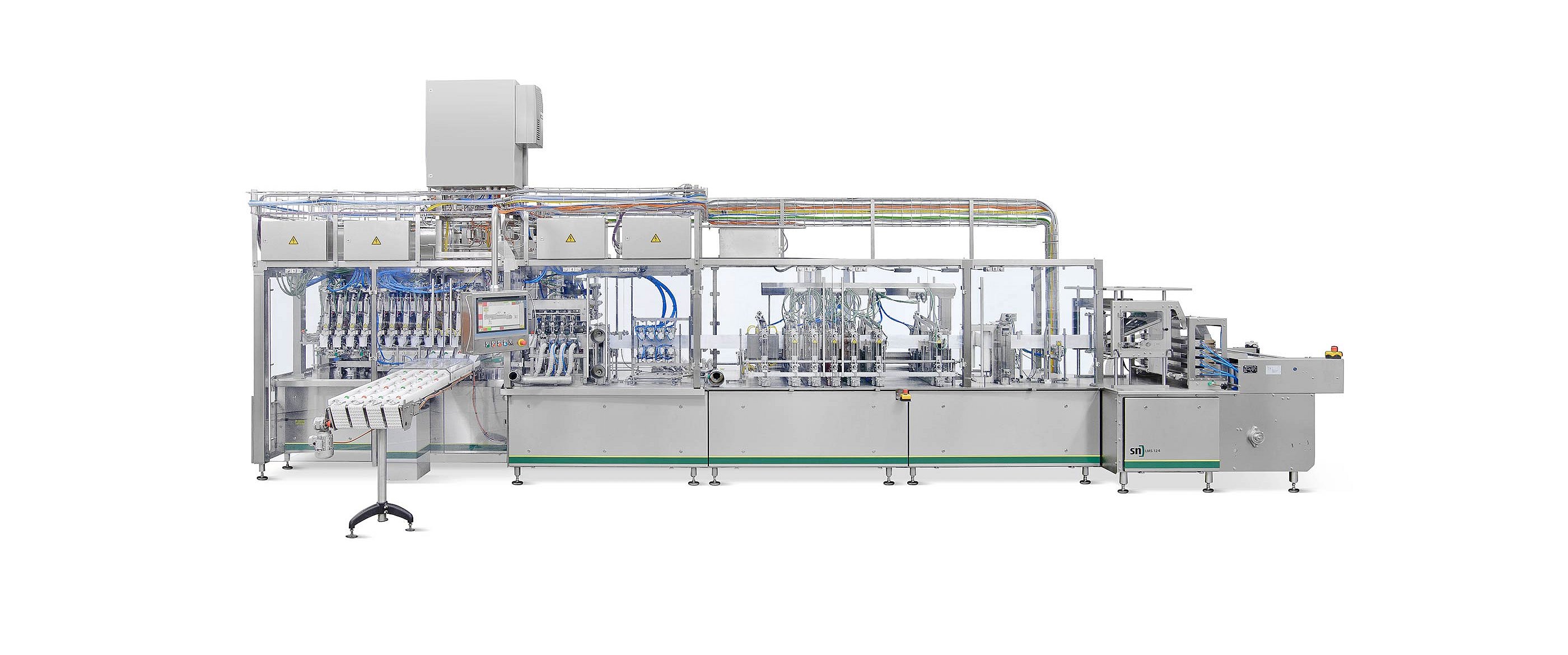

The LMS 120 of the spout series is ideally suited for producing spout pouches and filling liquids, whether for filling fruit yogurt in stand-up pouches with a center spout or liquid soap in stand-up pouches with a corner spout. Its simplex or duplex design offers the best conditions for small to medium output rates of up to 120 pouches per minute.

The qualitative and efficient processing of recyclable packaging materials, such as mono materials, is possible.

Pouch size width

50 – 200 mm

Pouch size length

80 – 350 mm

Max. machine output

up to 60 pouches/min.

Power consumption

approx. 7,5 – 10 kVA

Electricity supply

3 x 400/230V + N + PE, 50/60 HZ

Air consumption

approx. 550 Nl/min, 6 bar

Machine dimensions L x W x H

approx. 4.800 x 1.950 x 2.200 mm

((Data depending on configuration, filling characteristics, and pouch size)

Pouch size width

50 – 100 mm

Pouch size length

80 – 250 mm

Max. machine output

up to 120 pouches/min.

Power consumption

approx. 7.5 – 10 kVA

Electricity supply

3 x 400/230V + N + PE, 50/60 HZ

Air consumption

approx. 650 Nl/min, 6 bar

Machine dimensions L x W x H

approx. 4.800 x 1.950 x 2.200 mm

(Data depending on configuration, filling characteristics, and pouch size)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de