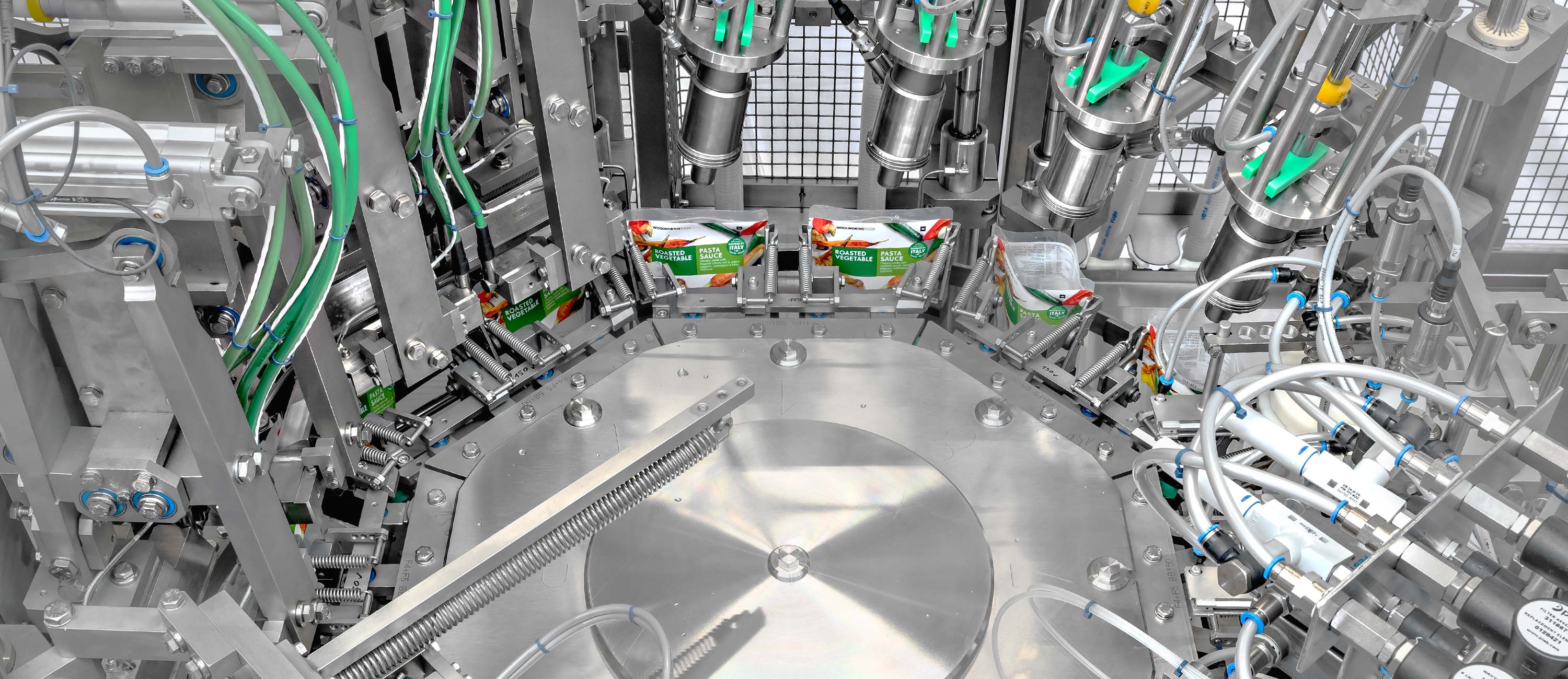

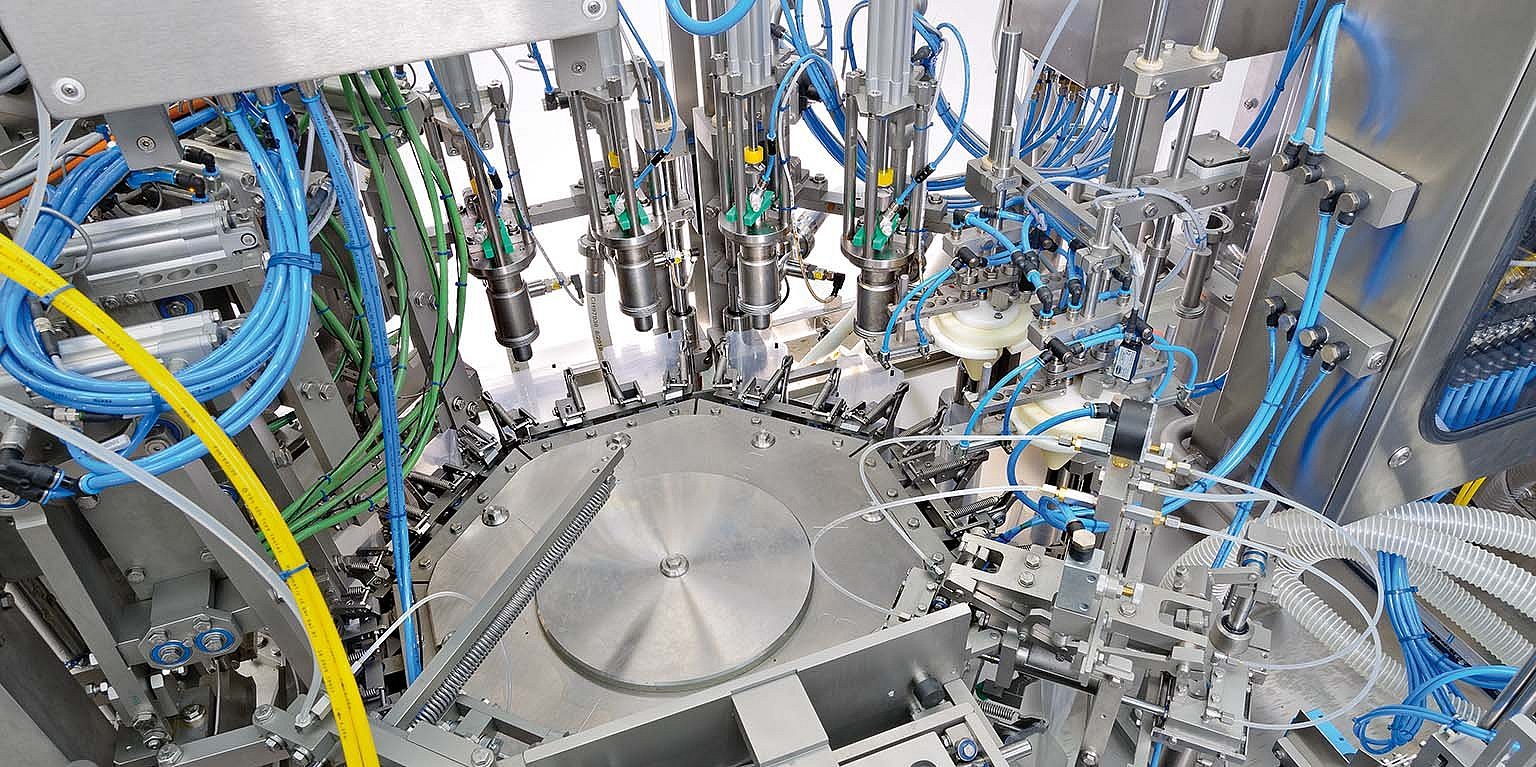

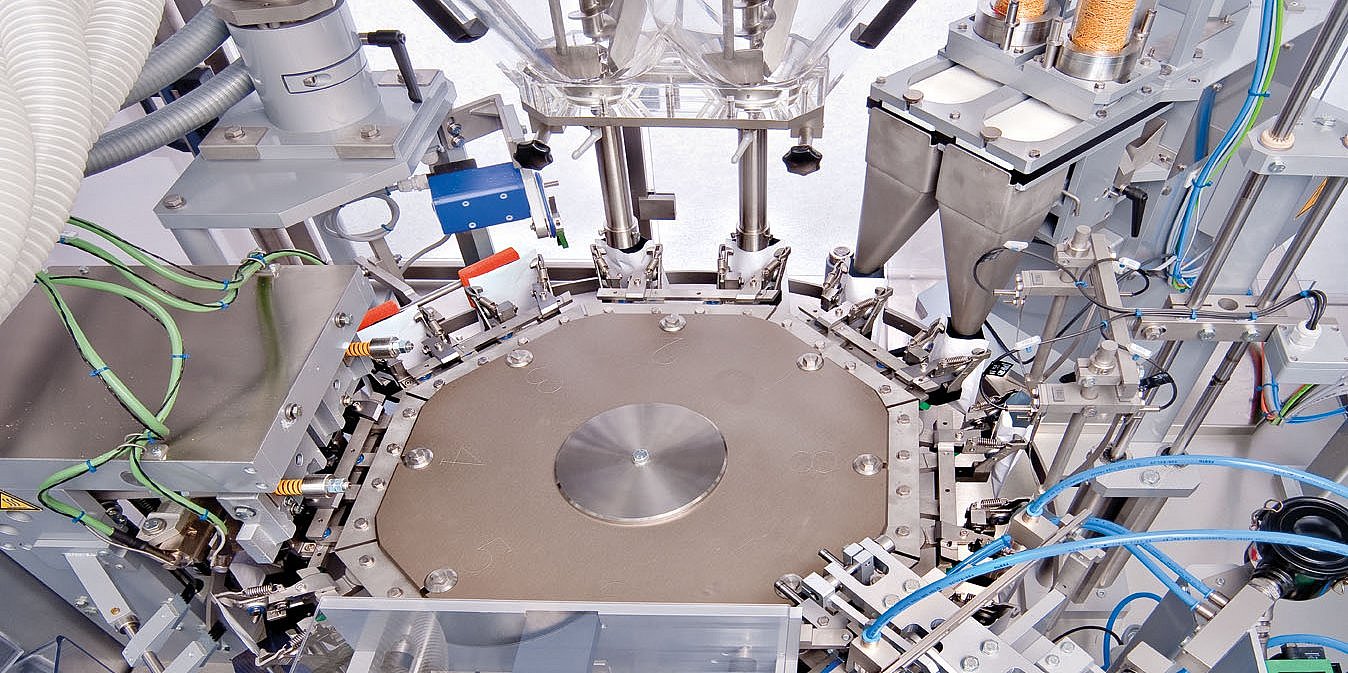

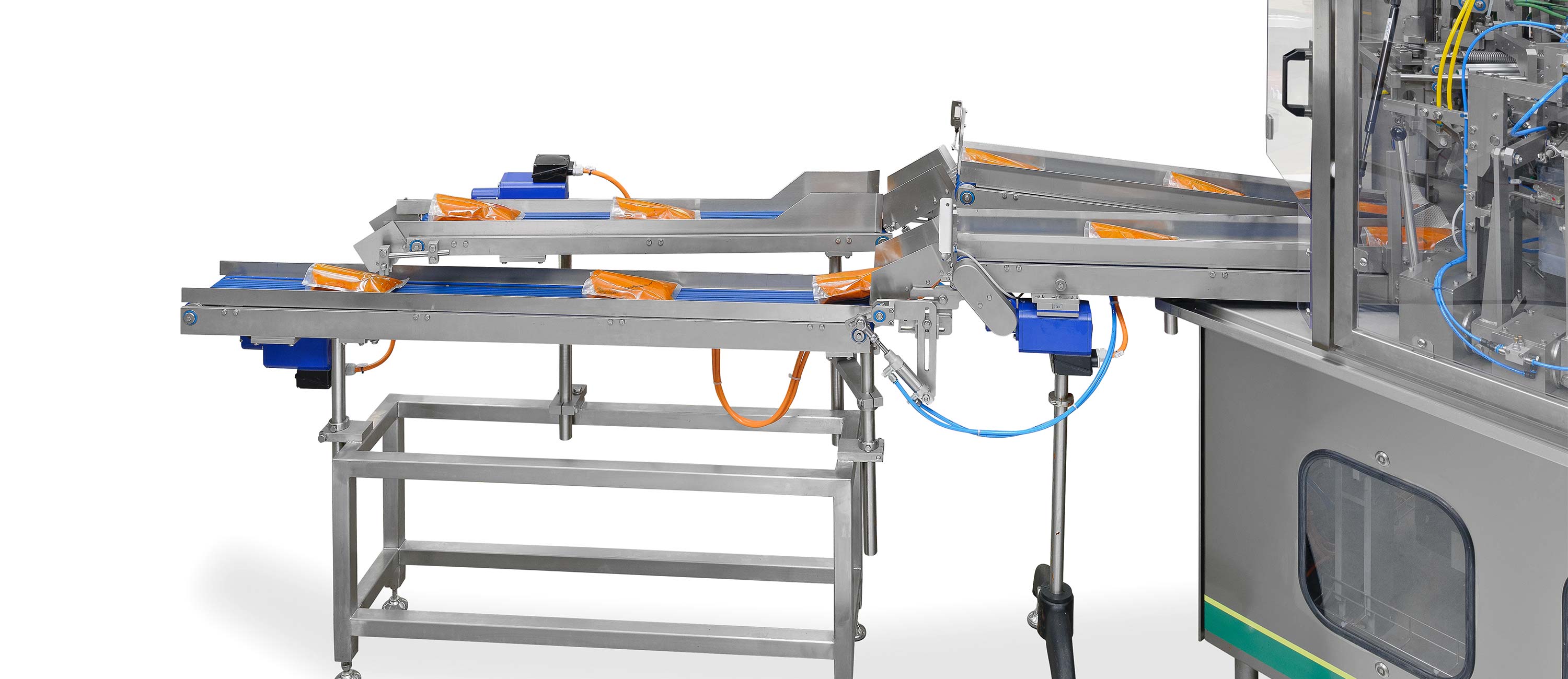

Our FBM 20 FS horizontal pouch packaging machine is a flexible and customizable FS-Series Pro machine. With a large format range and the ability to work with pre-made pouches, it is ideal for flexible applications and output ranges of up to 120 pouches per minute. It can be individually adapted to your requirements and can also be designed for wet operation, for example. With its small footprint, it is the perfect all-rounder for flexible pouch packaging.

The high-quality and efficient processing of recyclable packaging materials, such as mono-materials made of plastic or paper, is of course possible.

Application range

dry food, liquid food, pet food, pharmaceuticals, cosmetic & personal care, non-food

Pouch size width

100 – 300 mm

Pouch size length

120 – 350 mm

Max. machine output

up to 60 pouches/min.

Power consumption

approx. 15 - 20 kVA

Electricity supply

3 x 400/230V + N + PE, 50/60 HZ

Air consumption

approx. 650 Nl/min, 6 bar

Machine dimensions L x W x H

approx. 2.500 x 2.450 x 2.500 mm

(Data depending on configuration, filling characteristics, and pouch size)

Pouch size width

80 – 150 mm

Pouch size length

120 – 350 mm

Max. machine output

up to 120 pouches/min.

Power consumption

approx. 15 - 20 kVA

Electricity supply

3 x 400/230V + N + PE, 50/60 HZ

Air consumption

approx. 650 Nl/min, 6 bar

Machine dimensions L x W x H

approx. 2.500 x 2.450 x 2.500 mm

(Data depending on configuration, filling characteristics, and pouch size)

Contact

We are happy to support you in your pouch packaging project with customized machine and dosing technology.

We look forward to your inquiry.

Phone: +49 2267 699-0

Email: sales@sn-packaging.de